This coating covers more than 70 of the diameter of the lighted length of the lamp.

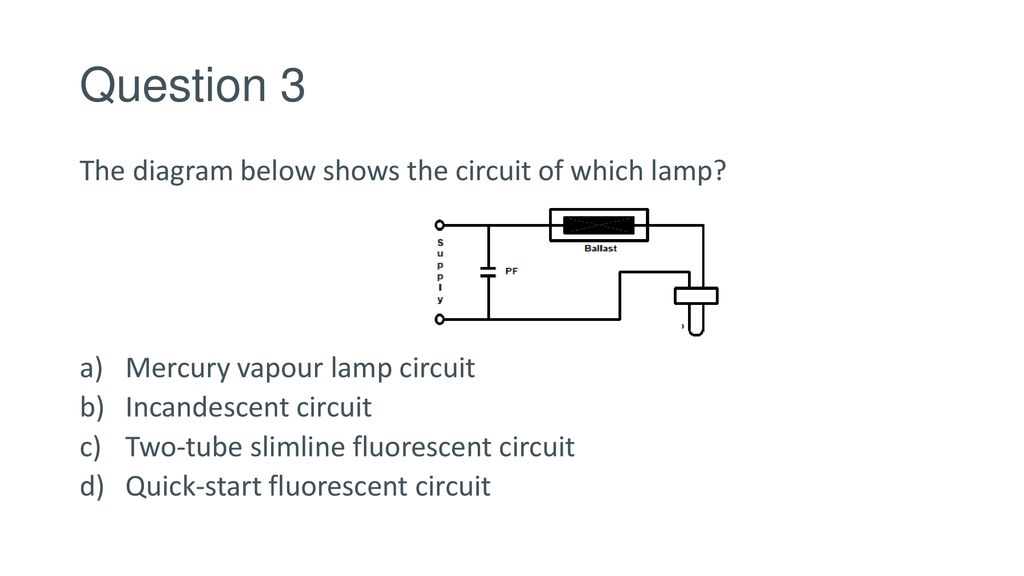

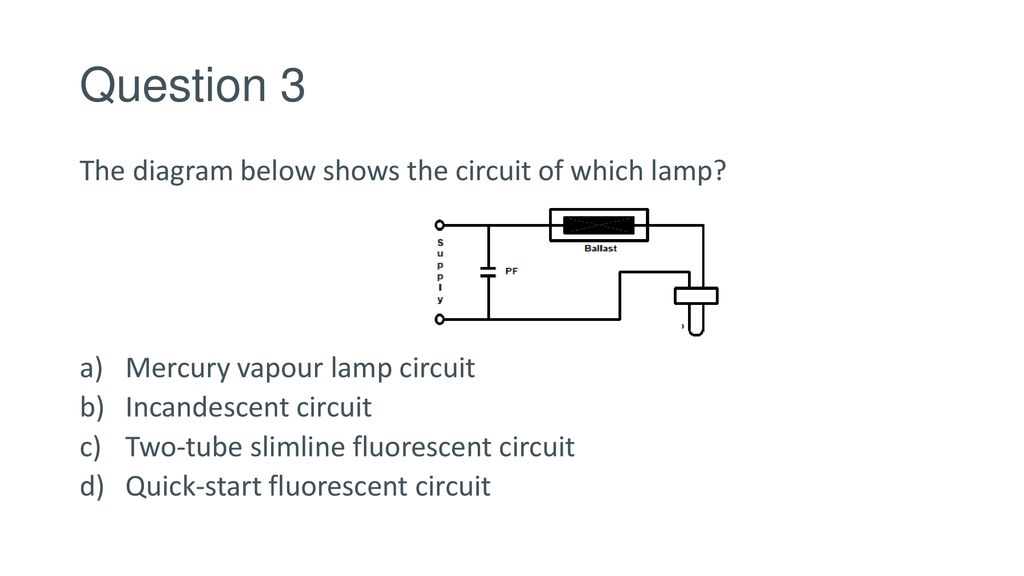

Low pressure mercury vapour lamp circuit diagram.

Low pressure and high pressure low pressure sodium lamps are highly efficient electrical light sources but their yellow light restricts applications to outdoor lighting such as street lamps where they are widely used.

Rather than a cold spot the lamp s amalgam spot on pellet regulates mercury vapor pressure during operation and yields up to three times the uvc output of a standard low pressure mercury lamp of the same length.

A sodium vapor lamp is a gas discharge lamp that uses sodium in an excited state to produce light at a characteristic wavelength near 589 nm.

A fluorescent lamp is a low weight mercury vapour lamp that uses fluorescence to deliver visible light.

As pressure increases the chance of multiple collisions gets increased.

As the main arc strikes and the gas heats up and increases in pressure the light shifts into the visible range and the high gas pressure causes.

Amalgam lamps use a mercury amalgam mix to control mercury vapor pressure.

An electric current in the gas energizes mercury vapor which delivers ultraviolet radiation through discharge process and the ultraviolet radiation causes the phosphor coating of the lamp inner wall to radiate visible light.

In case of fluorescent lamp the mercury vapour pressure is maintained at lower level such that 60 of the total input energy gets converted into 253 7 nm single line.

The aperture phosphor coated lamps that jelight company produces employ the same basic design as the double bore low pressure mercury vapor lamps with the exception of a special phosphor coating.